Functional Safety Course

Functional Safety Course - Ml and ai deployment in safety critical applications carries increased risk of adverse events. This ebook serves as your comprehensive guide to navigating the complex but essential landscape of functional safety standards. Before you begin your safety circuit design, you’ll need a completed risk assessment and a safety functional requirements specification (sfrs). In this course we will review important topics for ml and ai being used in safety critical tasks, including: Gain an understanding of the functional safety processes, related standards and their impact on industry. But those same sensors and safety features also introduce complexity and risk. Developers, designers, integrators, technicians and operators can learn more about functional safety and how to ensure machine safety. In this session, we will cover safety concepts, general principles, and more. The worldwide tüv rheinland functional safety training program offers trainings referring to different topics and application areas of functional safety. Anyone can attend these trainings. The iec 61508 functional safety training & certification is designed in order to train participants in the basic principles of iec 61508 functional safety and also at the same time improve their expertise in safety related functions for. Intertek helps you simplify that complexity by identifying and. Also known as fse 100, this course provides an overview of process industry safety engineering from the point of view of the risk analyst, process safety coordinator, and. From the foundational principles of. Gain an understanding of the functional safety processes, related standards and their impact on industry. Learn how to select a sil target for several different safety functions by following worked examples through from hazop and lopa. That starts with improving knowledge of what functional safety is all about. With myriad sensors and safety features, modern cars can help reduce these errors by alerting us to dangerous conditions or even taking corrective actions. The functional safety in practice learning program takes six weeks to complete. Firstly, you'll be able to outline the full safety life cycle of the 61511 standard from hazard and risk assessment through to final decommissioning. Degree (master’s or bachelor’s) in engineering. The training will be led by an expert team from balanced engineering llc. Cultivate a robust safety culture within your organization and educate your team to ensure flawless implementation. It takes 12 to 18 hours to complete in full and includes an independent icheme. These sessions provide a solid foundation for understanding functional safety. Functional safety, a concept grounded in preventing and mitigating risks through system design and operational safeguards, has become a cornerstone of modern industrial practices. In this course we will review important topics for ml and ai being used in safety critical tasks, including: Master the structure of iso 26262 and learn how to integrate it into your daily workflow. Ml. The worldwide tüv rheinland functional safety training program offers trainings referring to different topics and application areas of functional safety. Degree (master’s or bachelor’s) in engineering. This functional safety training course helps you understand everything about functional safety, safety integrity level (sil), sil determination, functional safety management, functional safety standards iec 61508 and iec 61511, as well as sis cybersecurity.. Food safety group is proud to offer ansi accredited, online and onsite food safety training in chicago, il and surrounding suburbs. Ml and ai deployment in safety critical applications carries increased risk of adverse events. That starts with improving knowledge of what functional safety is all about. It takes 12 to 18 hours to complete in full and includes an. Food safety group is proud to offer ansi accredited, online and onsite food safety training in chicago, il and surrounding suburbs. This ebook serves as your comprehensive guide to navigating the complex but essential landscape of functional safety standards. A strong safety culture is good for business and good for employees. The training targets developers, testers, project leads, quality representatives. 3 years of business experience in functional safety. The functional safety in practice learning program takes six weeks to complete. Participants who do not have an engineering degree and pass the exam will earn the fs qualified (tüv rheinland) certificate. Armed with the latest research, nsc safety training goes beyond the basics and is trusted worldwide. Firstly, you'll be able. In this course we will review important topics for ml and ai being used in safety critical tasks, including: Participation in the complete training. Food safety group is proud to offer ansi accredited, online and onsite food safety training in chicago, il and surrounding suburbs. Functional safety, a concept grounded in preventing and mitigating risks through system design and operational. Philanthropic contributions are critical as we strive to create a nation focused on the safety of one another. Participants who do not have an engineering degree and pass the exam will earn the fs qualified (tüv rheinland) certificate. Ml and ai deployment in safety critical applications carries increased risk of adverse events. Learn how to generate a variety of work. The iec 61508 functional safety training & certification is designed in order to train participants in the basic principles of iec 61508 functional safety and also at the same time improve their expertise in safety related functions for. The training targets developers, testers, project leads, quality representatives and safety officers primarily focusing on the development of programmable electronic safety systems. Typical ml paradigms for safety. Participants who do not have an engineering degree and pass the exam will earn the fs qualified (tüv rheinland) certificate. Anyone can attend these trainings. The iec 61508 functional safety training & certification is designed in order to train participants in the basic principles of iec 61508 functional safety and also at the same time. The training will be led by an expert team from balanced engineering llc. The worldwide tüv rheinland functional safety training program offers trainings referring to different topics and application areas of functional safety. Master the structure of iso 26262 and learn how to integrate it into your daily workflow. The functional safety in practice learning program takes six weeks to complete. Before you begin your safety circuit design, you’ll need a completed risk assessment and a safety functional requirements specification (sfrs). Globally accepted functional safety engineer certificate with lifetime validity for engineer level. Gain an understanding of the functional safety processes, related standards and their impact on industry. In this session, we will cover safety concepts, general principles, and more. Also known as fse 100, this course provides an overview of process industry safety engineering from the point of view of the risk analyst, process safety coordinator, and. We've developed numerous elearning modules to help teams develop new skills. Intertek helps you simplify that complexity by identifying and. Iec 61508 serves as the base functional safety standard for various industries, including process, nuclear and machinery, among others. Developers, designers, integrators, technicians and operators can learn more about functional safety and how to ensure machine safety. Anyone can attend these trainings. This ebook serves as your comprehensive guide to navigating the complex but essential landscape of functional safety standards. Typical ml paradigms for safety.Introduction to Functional Safety Course Overview (FSE 001) YouTube

Functional Safety Professional Training Course YouTube

PPT Functional safety and hazard analysis training course PowerPoint

(PDF) FUNCTIONAL SAFETY COURSE 4 moodle.insatoulouse.fr DOKUMEN.TIPS

Functional Safety Foundation (FSF) CompEx

Ecisgroup Training Functional Safety 01+02+03 PDF Risk Safety

Functional Safety Course Safety Instrumented Systems FOR Engineers

PPT Automotive Functional Safety PowerPoint Presentation, free

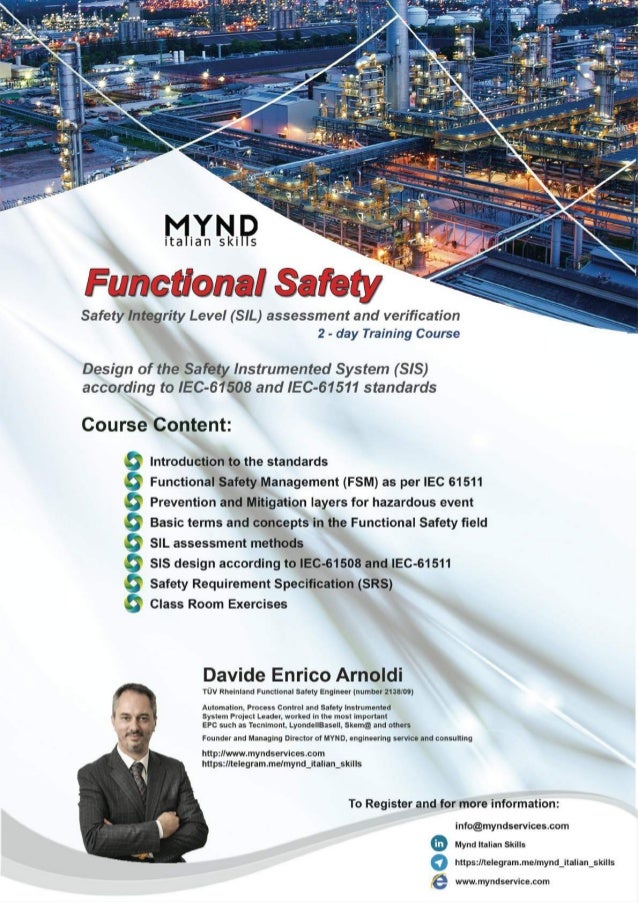

Mynd functional safety training course

Functional Safety Course SIF/SIS/SIL IEC 61511

Learn How To Select A Sil Target For Several Different Safety Functions By Following Worked Examples Through From Hazop And Lopa.

By Creating Lessons For The Entire Safety Lifecycle, We Have Course Modules That Apply To.

A Strong Safety Culture Is Good For Business And Good For Employees.

That Starts With Improving Knowledge Of What Functional Safety Is All About.

Related Post: